PLC (Programmable Logic Controller)

Modular programmable logic controller (PLC) featuring high-speeds and expanded memory. Easily record all PLC data with synchronized video to quickly diagnose and troubleshoot when a production error occurs. These PLCs also seamlessly connect to other factory automation sensors and devices.

Product Lineup

Next-generation PLC: Adopting Quad Core CPU with ultra-high speed and large-capacity, 256 EtherNet/IP™ connections and OPC UA via CPU communication port. Operation recorder function saves “all variables/all devices/cameras/events” data before and after the trouble occurs. Throughout debugging to maintenance, KV-X Series differentiate your machine performance.

Features

Optimal Hardware Specs for Machine Control

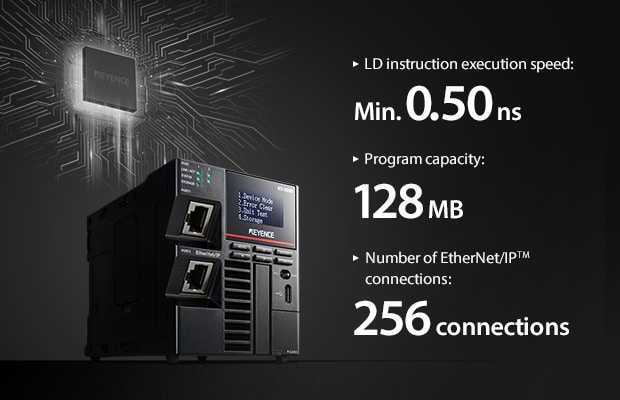

- LD instruction execution speed Min. 0.50 ns, more stable control with high speed processor.

- Program capacity 128 MB, 1 CPU model covers wide range of applications.

- Number of EtherNet/IPTM connections 256, support big network with CPU port.

Resolve Problems Quickly with the Machine Operation Recorder Function

The Machine Operation Recorder function records all equipment information before and after a shutdown.

This enables immediate identification of the cause of the problem, allowing for shortened recovery time and improved operational availability through fundamental countermeasures.

- Recording : All equipment data from devices, cameras, and events are automatically recorded.

- Playback : View linked playback of various data sources recorded from the moments before the problem occurred.

- Analysis : Automatically analyze ladder programs and view tree diagrams of related devices.

Features

Resolve Problems Quickly with the Machine Operation Recorder Function

The Machine Operation Recorder function records all equipment information before and after a shutdown.

This enables immediate identification of the cause of the problem, allowing for shortened recovery time and improved operational availability through fundamental countermeasures.

- Recording : All equipment data from devices, cameras, and events are automatically recorded.

- Playback : View linked playback of various data sources recorded from the moments before the problem occurred.

- Analysis : Automatically analyze ladder programs and view tree diagrams of related devices.

Recording

Playback

Analysis

Prevent Problems with Symptom Monitoring

Constantly monitor the cycle time, device operating times, and waveform data (temperature, pressure, torque, etc.) for each scan cycle. Alerts for equipment behavior changes help prevent problems before they start.

Program-less Communication Options with KV-X COM

- Connect seamlessly to factory automation devices and PLCs

- Program-less PLC networking capability that supports 4 major industrial networks

Use KV-X MOTION for Positioning/Motion Control

- Program with drag/drop code or function blocks

- Synchronize motion across multiple axes

- Motion programs do not affect PLC scan time

KV-8000A with Built-In OPC UA Server Function

- Connectable to various devices and upper level systems via an international standard

- Advanced security ensures safe data communication

- Easily configurable with no intermediate PC required

A programmable logic controller, or PLC, has a built-in microcomputer (central processing unit (CPU)) and memory (storage element).

These useful devices operate with external input devices (push button switches and limit switches) that are mounted on the operating panel or system and allow you to freely control external output devices, such as indicator lights and solenoids.

Programs are written into the PLC memory from a computer installed that has dedicated ladder programming software installed.

PLC structure

Benefits of PLC (Programmable Logic Controller)

Compared to PLCs, conventional relay circuits can require quite a few relays, timers, and counters depending on the number of input and output devices as well as the design of the control circuit. Any addition or change in the relay circuit due to adding devices leads to time and costs spent revising the wiring.

With a PLC, you can easily modify circuits with additions and changes to the dedicated program. Even large-scale circuit design can be dealt with using just one PLC.

Function extension units are available to allow PLCs to handle various use cases. A dedicated program instruction language is provided for each unit, which allows for design of and changes to program circuits regardless of the complexity of the control.

Compared to circuits built only using large numbers of contact relays, PLCs use relays for input and output units as necessary. This keeps down the number of mechanical parts used in the circuitry design, which minimizes part replacement and improves ease of maintenance.

PLC (Programmable Logic Controller) Case Studies

Quality management with centralized flow rate monitoring

Simultaneous monitoring of multiple flow sensors is possible from the PLC. The ability to monitor sudden or gradual changes in flow rate from a central point helps improve quality control and energy savings.

Light curtain optical axis visualization

With the ability to monitor the received light intensity for each optical axis of a light curtain, PLCs can help prevent malfunctions by issuing an alarm if the intensity decreases due to dirt or vibrations.

Variation prevention (welding machines)

Uneven welding occurs when there is a difference between the sensor's measurement and the positioning command. With a PLC, the timing of the measured value (analog input unit) and of the positioning command (positioning unit) are synchronized with inter-unit synchronization, which eliminates variations and allows for stable welding. Furthermore, corrections are applied at high speed, which allows for control that is both high speed and high precision.

Increased measurement accuracy (profile measurement system)

In order to understand profile changes in more detail, the PLC’s sampling cycle need to be raised to increase the volume of sampling data per second.

The PLC’s buffering function allows for sampling of up to 100,000 data sets per second. Waveform comparison can be performed on the collected data within the PLC for inline pass/fail inspection.

Traceability system construction (processing, assembly, and inspection)

With a PLC, marking data scanned by the code reader and the manufacturing information of each process can be transmitted to the host computer as a CSV file.

The computer is not accessed at all times, which reduces the load on the network. Through an Ethernet connection between the PLC and the code reader, logging the matching level (the ease of reading) together with the read marking data makes it possible to check the marking quality at all times.

Frequently Asked Questions About PLC (Programmable Logic Controller)

A program format called ladder logic is most common, but the structured text (ST) language is also used.

Previously, different programming languages were used for different PLCs, but standardization of the programming language is progressing under International Standard IEC 61131-3 in order to improve user-friendliness. KEYENCE’s PLC, the KV Series, is compliant with IEC 61131-3.

It depends on the PLC manufacturer and series. With the KV Series, you can directly connect units together without any base.