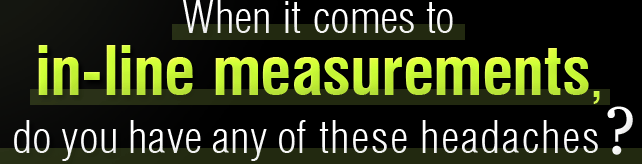

It takes too much time and effort

to measure a variety of dimensions at multiple locations.

Is it possible to reduce the measurement time?

Just place the target

to measure a maximum of 16 dimensions simultaneously!

This makes it possible to reduce the measurement time!

The TM-3000 will measure outer diameter, step, and angle at the same time. This eliminates problems that occur when repositioning the target.

Download catalog

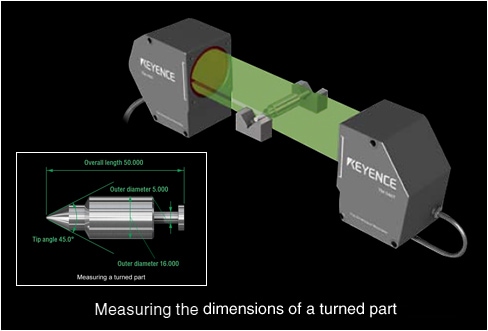

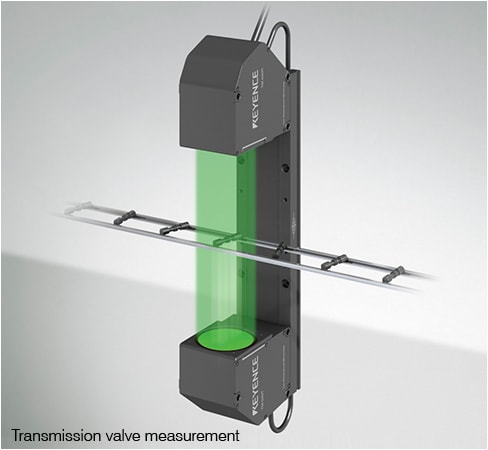

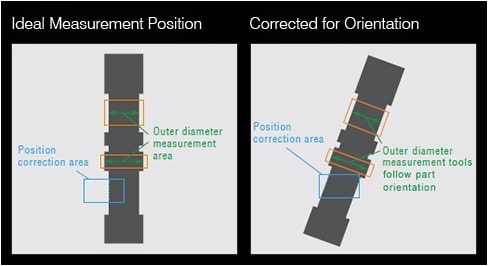

During in-line measurements,

I can't get the correct measurements

because of part orientation, and tilt in the fixture.

Can the TM-3000 compensate for this problem?

Even when objects are conveyed in random orientations,

automatic correction ensures that accurate measurements are performed!

The TM-3000 has position correction tools that enable the system to accurately measure parts presented in a random orientation, or when it's difficult to position parts consistently.

Download catalog

When setting up my vision systems,

I have difficulty calibrating the field of view to

read accurate dimensions.

Is there a NIST traceable, pre-calibrated system out there?

TM-3000 uses telecentric lenses with a fixed field of view.

This enables pre-calibration in engineering units, not pixels.

TM delivers out-of-box accuracy unaffected by depth of field.

Why TM-3000?

- 1) Increase confidence in your inspection processes by using reliable, low maintenence, measurement systems.

- 2) Save headaches and time spent choosing lenses, lighting, designing fixtures, and calibrating.

Download catalog